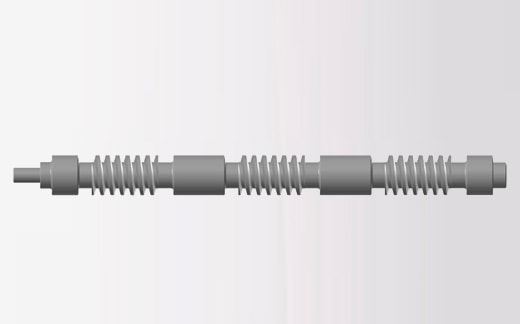

Worm Drive Unit for the Machinery Manufacturing Industry

The worm drive unit highlighted here operates behind the scenes in a globally recognized amusement park ride in Florida that receives hundreds of thousands of visitors annually. It goes without saying that in order for this project to be a success, the finished unit would have to exhibit an elevated level of quality to provide a long and trouble-free service life.

At Tracey Gear & Precision Shaft, we manufactured the worm drive unit to ensure reliable, continuous duty use with minimal maintenance requirements. Featuring overall dimensions of 38.5”, the material of construction was 4150 HT resulphurized steel, which exhibits good overall strength and toughness in the heat-treated condition. Production involved a strategic sequence of operations for achieving the quality criteria outlined in the customer specifications.

Heat-treating the steel to Rc 32-35 enabled us to improve its machinability and facilitate rough generation of the threads. After machining the threads, we used high-frequency induction heating, which minimizes distortion and generates a very accurate heating pattern, for attaining thread hardness of Rc 53-58. After stress relieving by treating at 450°F – 500°F temperatures for a minimum of two hours and air-cooling, we inspected the workpiece for straightness. Additional processes involved finish machining as well as grinding and polishing the thread surfaces and the 3.0” diameter bearing surfaces to an RMS 8 finish.

Along with our standard in-process/final test and measurement procedures, quality assurance consisted of using a large bench center to verify concentricity as well as magnetic particle inspection to confirm the part was free of discontinuities and surface cracks. We shipped the workpiece to the customer accompanied by a formal inspection report documenting all of the quality criteria.

Contact us directly for more information about our precision worm drive manufacturing capabilities.